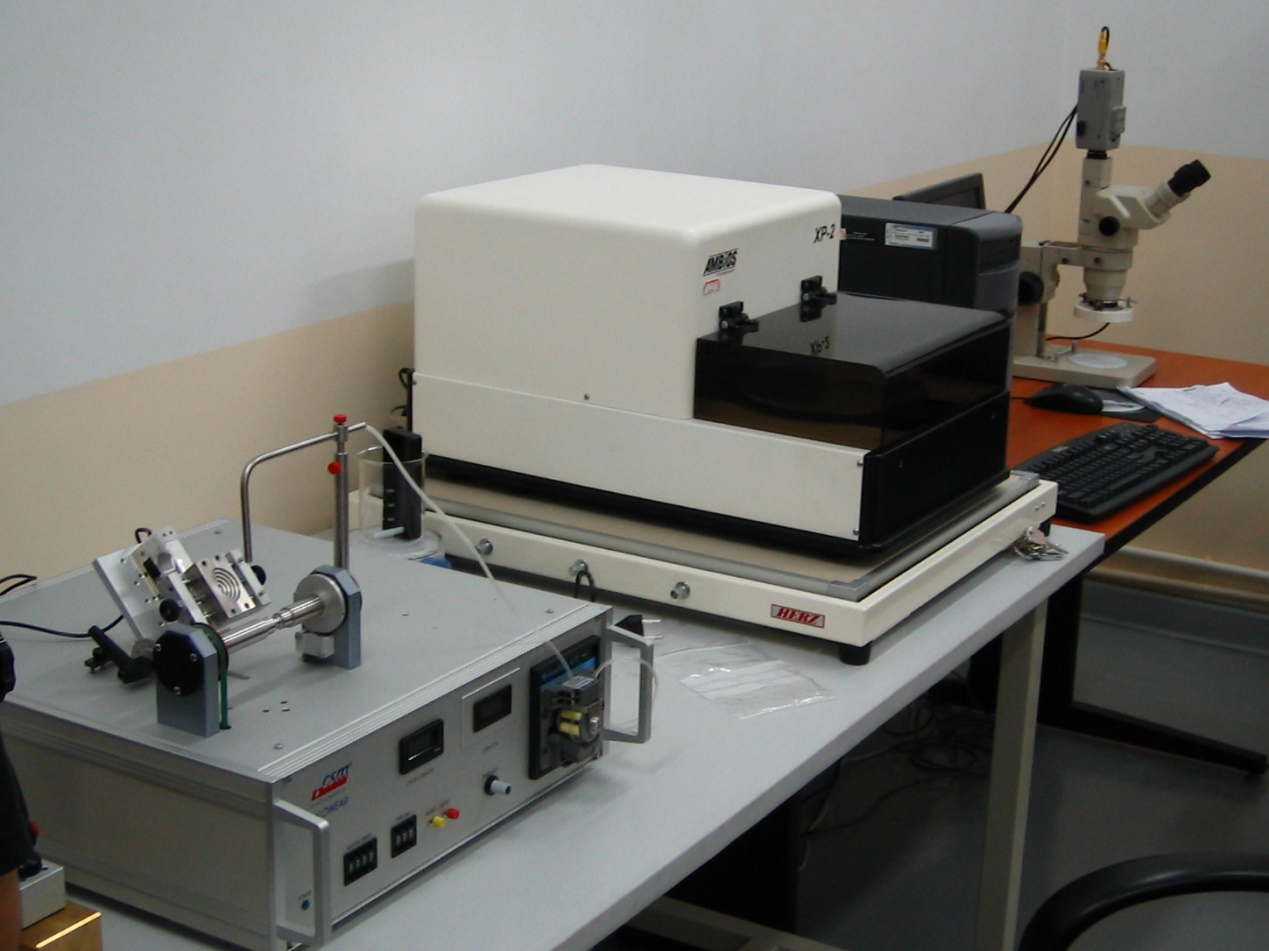

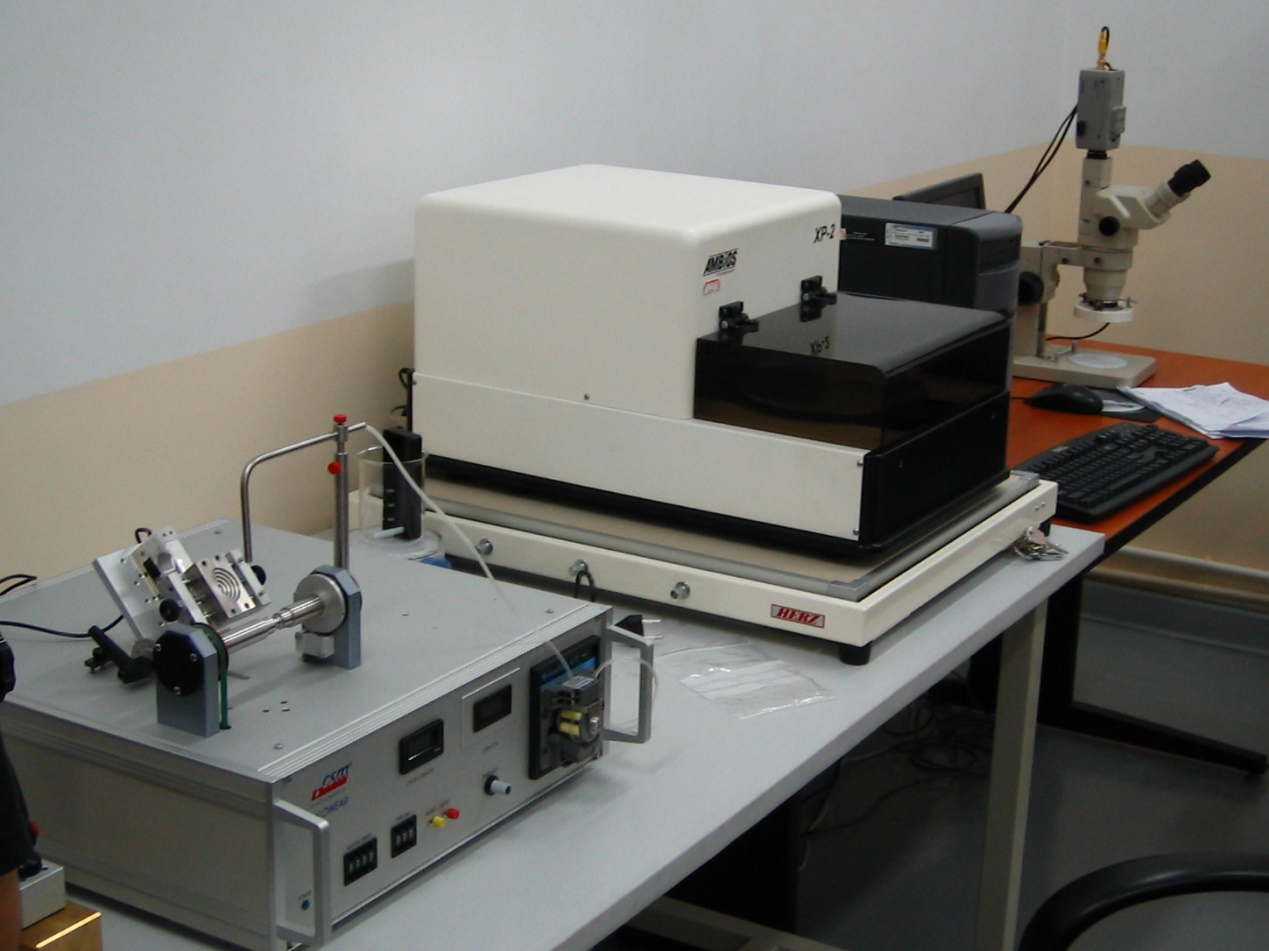

HiNa-Carbon series PVD coating equipment is a high-quality, industrial grade Diamond-like Carbon (DLC) film coating equipment, integrating enhanced magnetron sputtering and ion beam and other technologies, using the unique process and design independently developed by INA coating. The coating products provided by HiNa -Carbon coating equipment can be used in the fields of automation parts, automotive parts, textile parts and tools. The HiNa-Carbon coating equipment provided by Huinano- coating Co,.Ltd has good process stability, and the related process can also be customized according to customer needs to meet the market demand of customers.

| General Specificationgs Of HiNa-Carbon Coating System |

Overall size of coating equipment (mm) | 2400(W) x2400(D)x2000(H) |

Power of equipment | 50(kW),380(volt) three-phase |

Compressed air and cooling water | 0.46~0.60 mpa, 1.5 m3 / min The target source is cooled at 25°C and the cavity is cooled at 35°C |

Vacuum pumping system | Mechanical selection pump 1

1 molecular pump | 200 cubic meters/hours 2500 liters per second | Load free system limit vacuum 1.0x10-4 pa |

Vacuum measuring system | Low vacuum/resistance gauge /2 channels

High vacuum/child gauge /1 way |

Coated ion source and power supply (power supply can be selected according to customer requirements) | Magnetron sputtering source 1 set

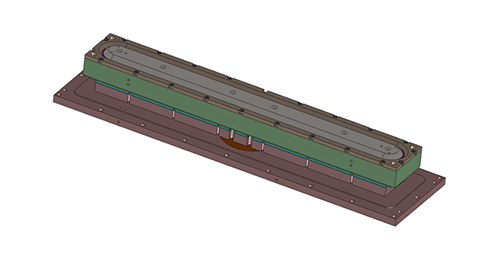

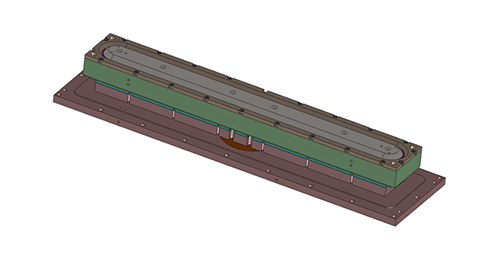

2 sets of ion beam source 1 set of magnetron sputtering power supply 2 sets of ion beam power supply 1 set of bias power supply | The target source size is 664x85 mm

Anode layer ion beam Direct current power supply High voltage DC pulse power supply | Target power <10 kW

The effective operating voltage is 1500 volts Power supply 10 kW, duty cycle 0~90%, frequency 40 kilohertz |

Process gas | Independent 2 channels, mass flow controller MFC (independent gas channels can be added according to customer needs) |

Workpiece turning frame | 2 sets, with 12 independent rotating planetary turret with a diameter of 120 mm, can be loaded and unloaded together with the plated workpiece, rotating speed ~10 RPM, rotating frame size diameter of 730 mm, carrying weight of 350 kg |

Coating machine control system | PLC control system + industrial PC/PLC

The system has three operating modes: automatic, manual and maintenance So all the operating parameters are recorded in the computer for analysis and reference Open software interface, users can develop their own process |

Coating process | Diamond-like (DLC) coating processes and auxiliary processes for automotive parts and tools are included |

The enhanced magnetic-controlled cathode ARC technology is used in the PVD hard film coating equipment. The series of equipment can complete the coating covering all kinds of Metal coatings, such as: Titanium Nitride (TiN), Titanium Aluminum Nitride (TiAlN), Titanium Aluminum Chromium Nitride (TiAlCrN), Aluminum Chromium Nitride (AlCrN), Chromium Nitride (CrN), Titanium Nitride Carbon (TiCN) and so on, this kind of film can be widely used in tools, tools, molds and parts with high wear resistance requirements. Hi-Metal series coating equipment is a kind of industrial hard film coating equipment with good stability and high degree of automation.

| General Specificationgs Of HiNa-Metal Coating System |

Overall size of coating equipment (mm) | 2400(W) x2400(D)x2000(H) |

Power of equipment | 50(kW),380(volt) three-phase |

Compressed air and cooling water | 0.46~0.60 mpa, 1.5 m3 / min

The target source is cooled at 25°C and the cavity is cooled at 35°C |

Vacuum pumping system | Mechanical selection pump 1

1 molecular pump | 200 cubic meters/hours 2500 liters per second | Load free system limit vacuum 1.0x10-4 pa |

Vacuum measuring system | Low vacuum/resistance gauge /2 channels High vacuum/child gauge /1 way |

Magnetically controlled cathode target and power supply (power supply can be selected according to customer requirements) | Three sets of planar enhanced magnetron cathode arcs

3 sets of cathode arc power supply 1 set of bias power supply The maximum number of cathode arc targets is 4 | Target source size according to customer requirements

Dc arc power supply High voltage DC pulse power supply | Target current <150 amperage Effective operating voltage 25 volts Effective working current 180 amps 10 kW, duty cycle 0~90%, frequency 40 kilohertz |

Process gas | Independent 3-way, mass flow controller MFC (independent gas path can be added according to customer needs) |

Workpiece turning frame | 2 sets, with 8 diameter of 120 mm can independently rotate the planet turret, can be loaded and unloaded together with the plated workpiece, rotating speed ~10 RPM, the size of the turret diameter of 520 mm, carrying weight of 350 kg |

Coating machine control system | PLC control system + industrial PC/PLC

The system has three operating modes: automatic, manual and maintenance So all the operating parameters are recorded in the computer for analysis and reference Open software interface, users can develop their own process |

Coating process | 4 sets of mature diamond-like DLC coating process and auxiliary process are included |

Provide various ion source systems for customers

For example: enhanced cathode arc source

Filter type cathode arc source

Anode layer ion beam source

Magnetron sputtering source and so on

To provide customized plasma etching equipment, which can be used in semiconductor and electronics industries

To provide customers with all kinds of film testing equipment

Such as: coating thickness/ Calewear Test